CASE STUDY — Historical Building

STRUCTURAL INVESTIGATION OF A UNIQUE RESIDENTIAL AND MEETING FACILITY IN THE MIDDLE EAST

To facilitate planning of a proposed redevelopment and change of use, AQUILA carried out a preliminary assessment to help define future investigation work.

Project Impacts

The owner gained an overall impression of the facility’s condition

On the basis of this short initial assessment, with 109 non-destructive evaluations carried out in just 2.5 days, AQUILA was able to form an overall impression that the structure was built on the basis of a solid design and constructed in good quality, with key aspects such as concrete strength and uniformity, concrete cover to rebar, and rebar spacing showing little reason for concern.

Concrete strength could be evaluated without damaging the structure

To avoid drilling holes in concrete and taking samples for laboratory testing, AQUILA’s rebound hammer devices enable concrete’s compressive strength to be quickly estimated (each set of tests requiring only two minutes) with sufficient accuracy for most purposes – saving time and effort while also avoiding weakening the structure.

Key data could be quickly established, simply by scanning structural elements

AQUILA’s range of high-tech NDT scanning devices facilitate the investigation of details such as the amount of rebar in a concrete element and the depth of concrete cover – vital information when evaluating the load-bearing capacity and the durability of any reinforced concrete structure.

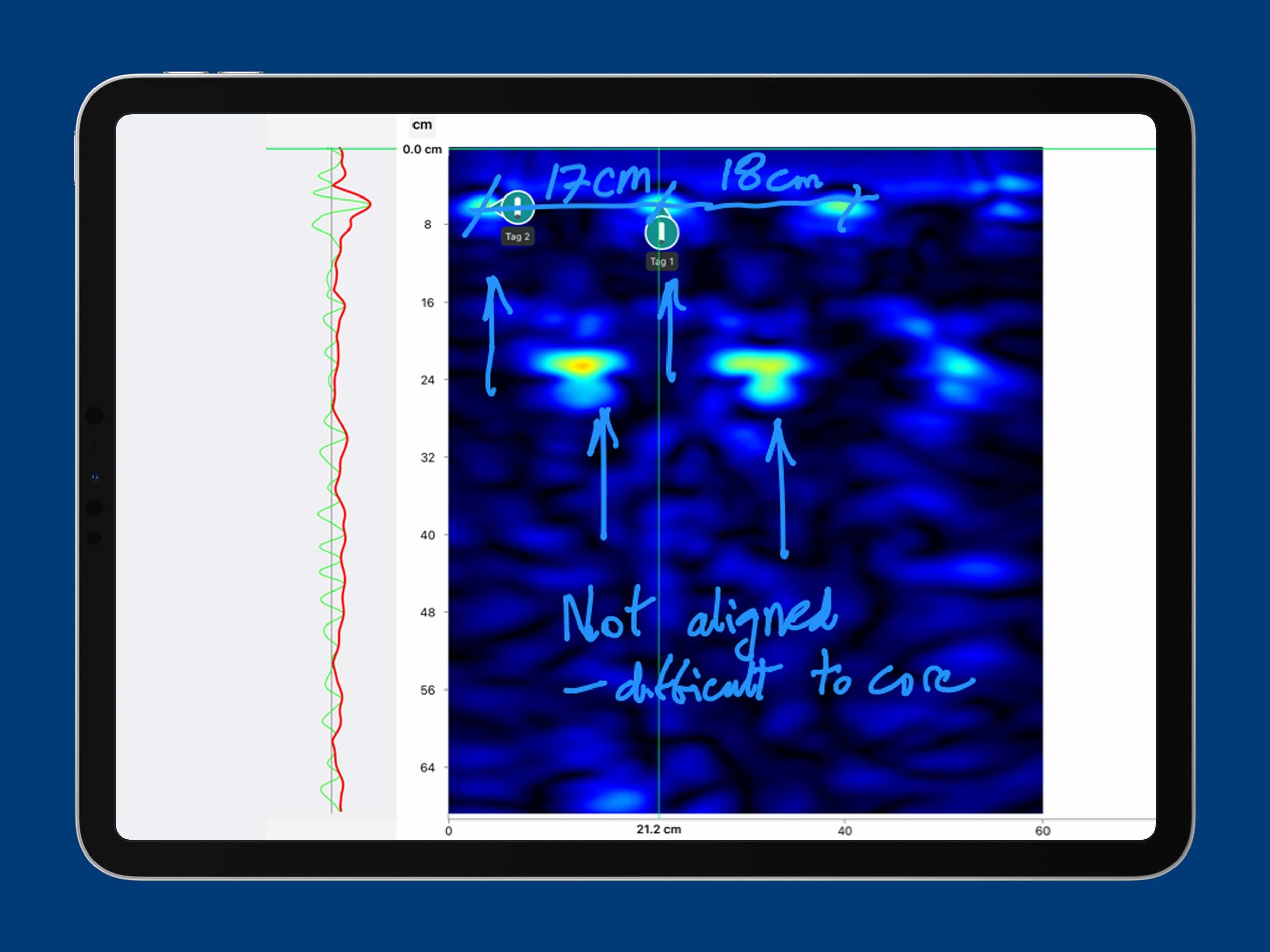

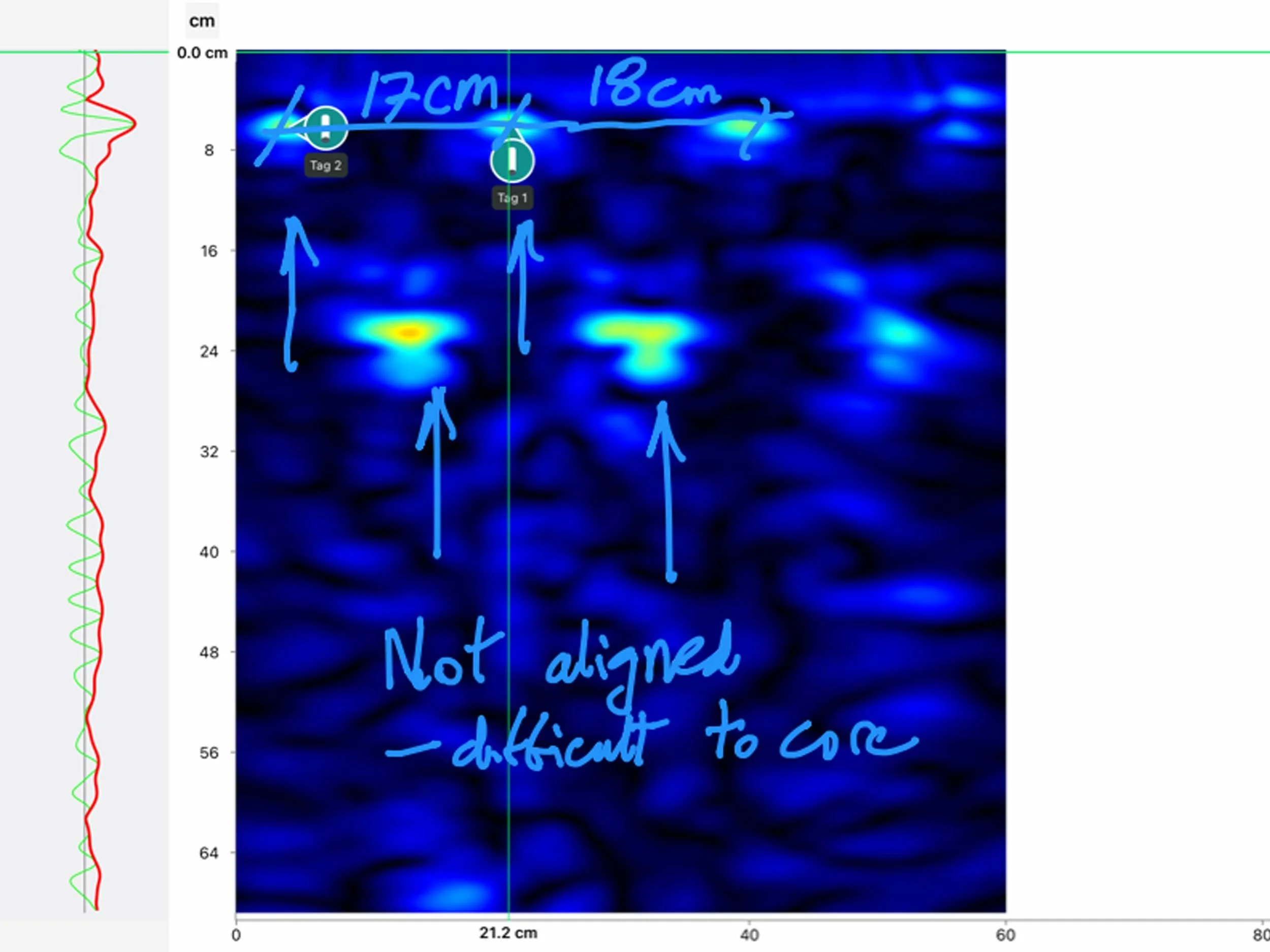

Scanning equipment provided immediate visualization of what is inside structural elements

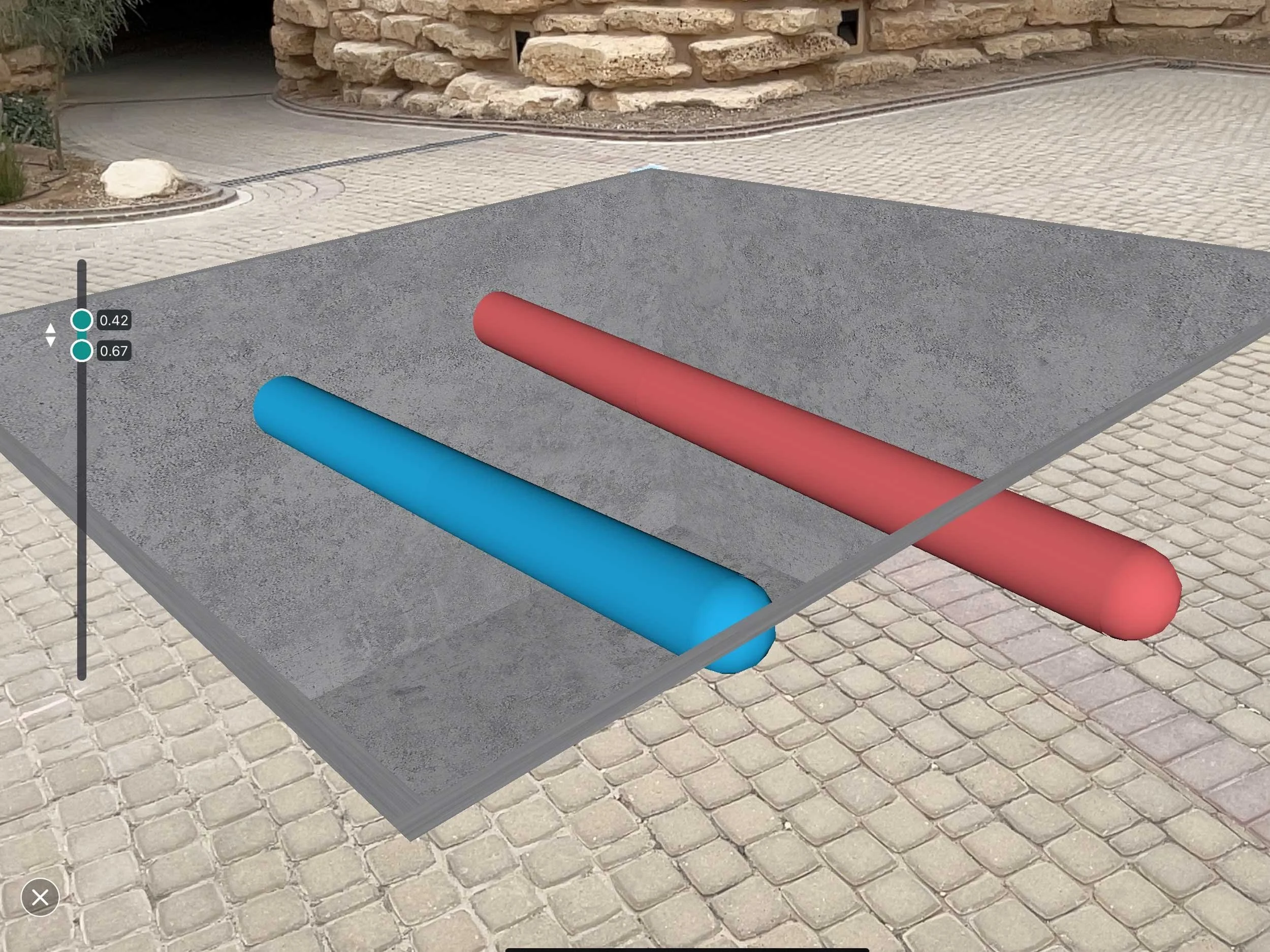

AQUILA’s NDT scanning devices also enable the layout of reinforcement steel and other elements or obstructions in walls and slabs to be visualized, using augmented reality where desired – a very useful feature that can support drilling, coring or cutting of structural elements without damaging key components.

The layout of services beneath the ground could be established without digging

Ground-penetrating radar equipment can be used to investigate and visualize the layout and depth of utilities, drainage pipes and other obstructions before carrying out excavation work – avoiding disruption to essential services (estimated, for example, to cost Canada over $1 billion every year) and saving associated expense and delays.

Facts & Figures

10

Ten types of non-destructive testing (NDT) device were used.

2.5

The entire assessment was completed in just 2.5 days, a tight timeframe for planning and execution.

9

Nine engineers conducted the structural investigation work, all working in unison, using the same cloud-based system in real time.

109

A total of 109 spots were assessed.

TECHNOLOGY OUTPUTS

EQUIPMENT USED

THE CHALLENGE

The owner of this exceptional property proposes to develop it into a luxury six-star hotel, and wished to gain a general understanding of its overall structural condition before progressing with detailed planning and design work. The owner also expressed a need to establish the existence and layout/depth of services and obstructions in external areas where new structures may be built. Challenges encountered included a lack of knowledge as to what future renovation works might entail.

AQUILA’S SOLUTION

Always able to deliver insightful results, even where needs are not yet clearly defined.

Thanks to the versatility of AQUILA’s equipment and solutions, a wide range of structural characteristics can be efficiently measured and recorded on a user-friendly cloud-based software platform, along with appropriate observations and recommendations. As a result, a great deal of knowledge can be stored in a way that is sure to be of interest to owners and engineers in relation to any future maintenance or asset development works.

The first step in preparation for the investigation work on site was to create a ‘digital twin’ for the facility in Screening Eagle’s INSPECT software platform. This was achieved using layout drawings provided by the client, and enables the investigation work carried out to be assigned to so-called “SPOTS” in the digital twin which define their location.

Then, using a wide range of high-tech non-destructive testing (NDT) equipment that was supplied by AQUILA’s sister company Screening Eagle, AQUILA’s personnel commenced a visual assessment of various areas of the facility, selecting SPOTS to investigate and record their observations with notes and photographs. In most cases, some form of NDT was carried out, with the recorded data transmitted directly from the NDT device to the INSPECT software using an iPad Pro. This all took place directly at the investigation location, enabling the entire team to be always up to date about all assessment work and making it possible for further specialists in remote locations to provide immediate support where required.

CLIENT BENEFITS

A wealth of investigation-based knowledge at the engineer’s fingertips.

Thanks to the industry-leading functionality of the NDT devices used, combined with the powerful and user-friendly INSPECT software platform for recording and presenting every observation and all measured data, graphs, photos and notes, a large amount of information regarding the facility’s as-built design and structural condition could be obtained and compiled in a short time on site. Full details of each investigated SPOT were then provided in a report at the touch of a button. This detailed report was supplemented with a short summary of the findings, with a particular focus on concrete strength, concrete cover and rebar spacing.

While most of the SPOTS contained simple measurements and observations, some include a great deal of information, which can be built on over time as new observations or measurements are added (e.g. from future assessments or following repair or modification work). For example, one image shows automatically generated key statistics from one SPOT concerning rebar cover and rebar spacing in a 75m-long concrete wall.

On the basis of the assessment carried out, AQUILA was able to form an overall impression that the structure was built on the basis of a solid design and constructed in good quality, with key aspects such as concrete strength and uniformity, concrete cover to rebar, and rebar spacing showing little reason for concern. A means of scanning walls and floors or external areas to establish the layout of utilities, rebars and other obstructions was also demonstrated, showing how associated challenges can be overcome in relation to future construction or modification work. With all pictures, videos and 2D/3D scans accessible via Screening Eagle’s secure INSPECT portal, the client’s engineers can review the findings and consider their consequences for the facility’s maintenance and development – with the findings of the assessment remaining available for reference at any time in the future, and the status of individual issues of concern being easy to update to reflect remedial action as and when it is carried out.

But the benefits of using high-tech structural investigation solutions such as these go far beyond any one particular structure or project!

The service and solutions provided by AQUILA on this project have been developed to acknowledge and address the challenges and megatrends of our time. The increasing demand for ever improving sustainability calls for the service life of existing structures and infrastructure to be extended wherever feasible, thereby minimizing embodied carbon and the unnecessary use of energy and materials – and this can be achieved by using state-of-the-art structural investigation technology to provide confidence in a structure’s condition or to enable renovation or repair works to be planned and implemented in an environmentally friendly way. Meanwhile, the workforce of tomorrow will increasingly demand digital, intuitive work processes and equipment that facilitate easy, real-time collaboration between specialists that may be on opposite sides of the world, with immediate generation of results and reports. AQUILA’s structural investigation services are designed to be future-oriented, optimized to meet these challenges in a sustainable way – benefitting not only the asset owner but also the environment and the wider society.

Technology used:

Application type:

Subsurface mapping using a GS8000 to establish layout of ducts, cables, pipework etc.

Debrief with client.